Assemblies & Components

Assemblies & components

Our range of services

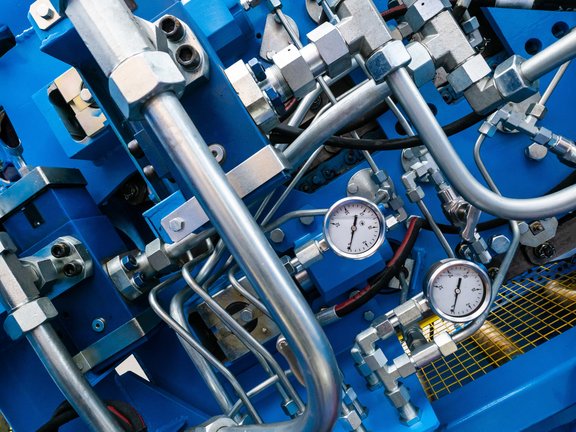

BUTTING manufactures stainless steel components from the prototype phase through to large-scale production. We offer you a wide range ofproduction services from a single source, including

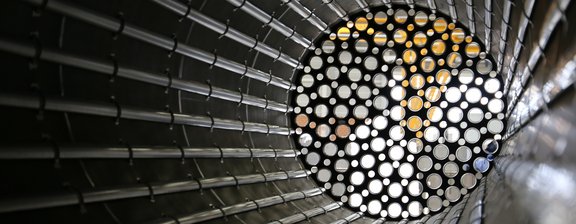

Our products fulfil a large number of standards and certifications for various industries, e.g. the nuclear industry or aerospace. We also offer you customised logistics solutions.

Wide range of possibilities

Your advantages

- Integrated manufacturing solutions: from pipe production to the finished component

- Everything from a single source: welding, processing, testing - efficient and with few interfaces

- Flexibly scalable: from individual items to large series

- Safe & reliable: certified quality and well-established processes

- Robust & lean: we manage stocks and deliver just-in-time directly to your production facility

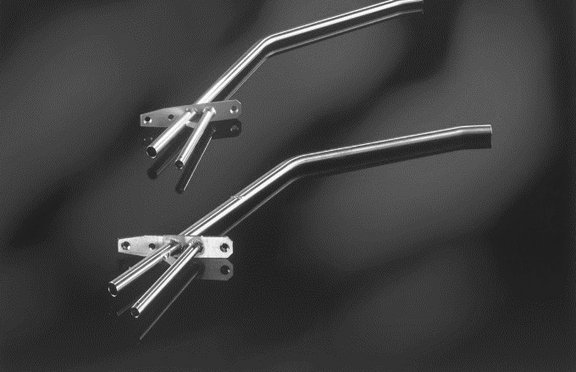

Product solutions

Application examples from A to Z

We manufacture components for

- Housings

- Components for exhaust systems

- Ductings and tanks

- Fluel lines for rockets

- Containers

- Drive rollers for food industries

- Tanks and pressure vessels for beverage bottling plants

- Elbows for metrology applications

- Bends for satellites

Can be found in many industries

Our solutions for your requirements

Our customised assemblies and components made of stainless steel are used in a wide variety of industries. Wherever reliability, precision and corrosion resistance are required, our customers trust in the quality of BUTTING.