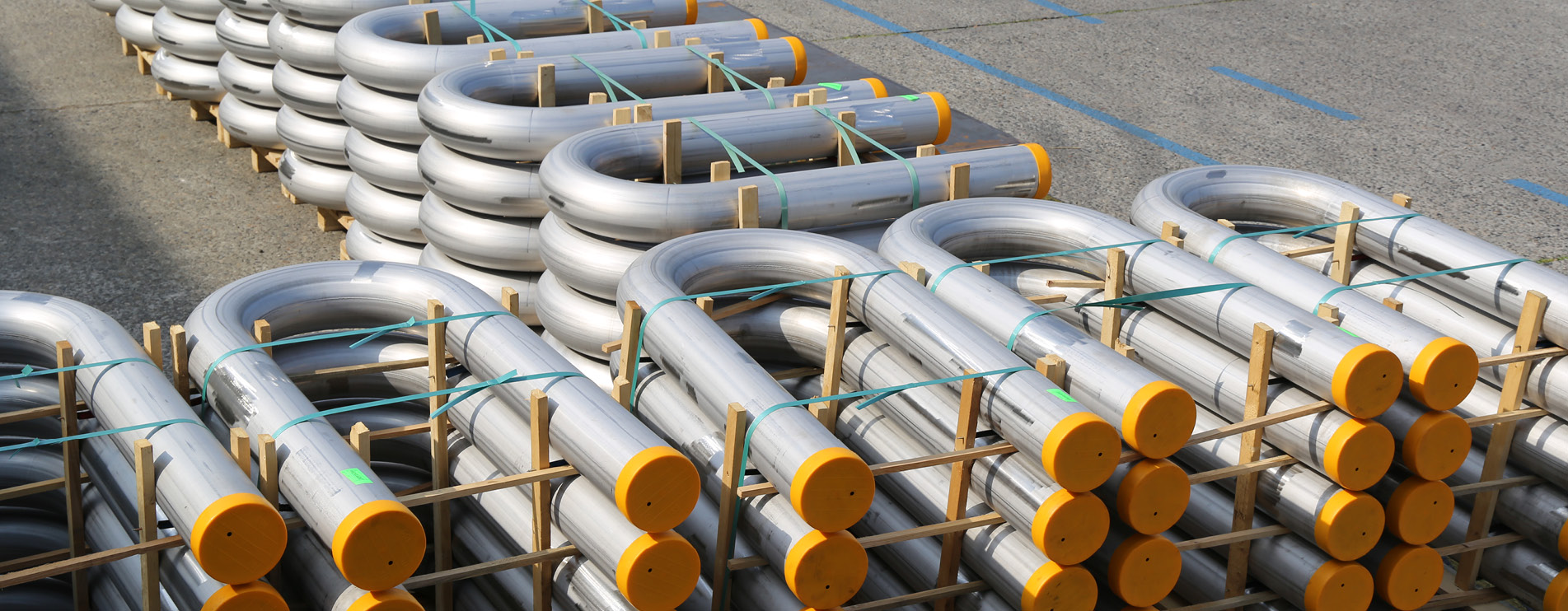

Since stainless steel made its entry into the industry, we have been offering longitudinally welded pipes in sizes from 18 to 3 000 mm with wall thicknesses of up to 70 mm.

Our products

Our business activity focuses on the processing of stainless steels, particularly special steels and clad materials, to create "tailor-made product solutions".

The latest from BUTTING

BUTTING honoured as a premium supplier

October 2024

BUTTING has been honoured by E. Hawle Armaturenwerke GmbH as a premium supplier. The company supplies Hawle with high-quality standpipes, which are an essential component of Hawle's well-known fire hydrants.

Stainless steel fitness equipment made by BUTTING

September 2024

Movement is the key to health and well-being – as BUTTING believes too. As a resident family business, the stainless steel processing company recently assisted,with the production and provision of fitness equipment, in the development of a new fitness trail in Knesebeck.

Sustainable and healthy: stainless steel drinking bottles for all employees

September 2024

The health of our employees is our top priority. For this reason, we have selected a high-quality raw material for our drinking bottles that is even better than previous plastic materials.

The BUTTING material “stainless steel” was considered to be the best material for our requirements.

Successful incident drill at BUTTING Könnern

August 2024

On 16 August 2024, a large-scale fire drill took place on the premises of BUTTING Könnern. As a so-called "hazardous incident plant" with potentially dangerous substances, the regular review and optimisation of safety precautions is important to the company.

Exhibition Dates

August-November 2024

Visit us at the following exhibitions:

>> UK Metals / Birmingham, GB / 11.09-12.09.2024

>> Hydrogen / Hamburg, DE / 23.10-24.10.2024

>> Space Tech Expo / Bremen, DE / 19.11-21.11.2024

Our team ist looking forward to meeting you!

The company

BUTTING is a company with tradition and history, with a profound basis in the past, and with great potential to actively shape the present and to plan the future.

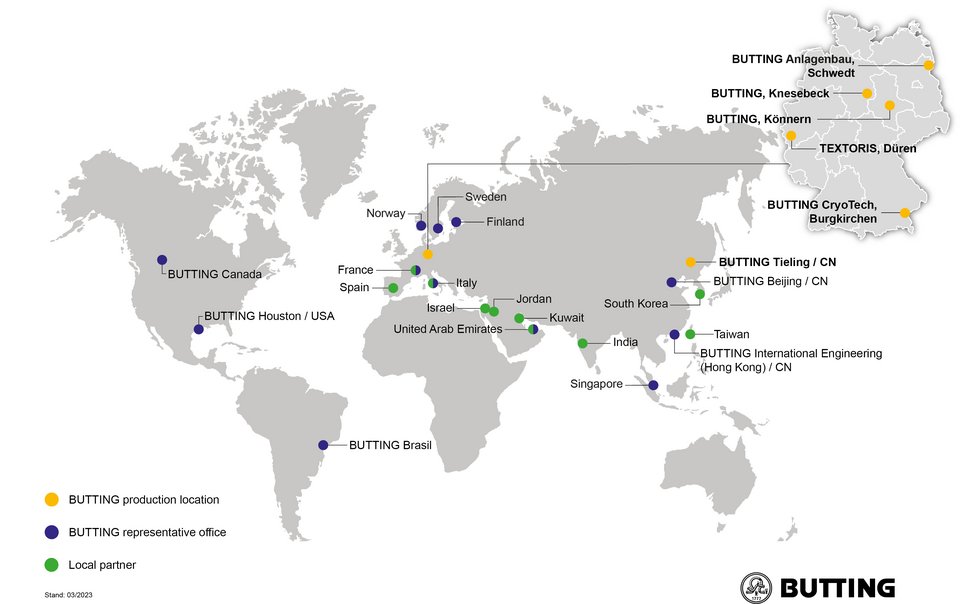

BUTTING worldwide

The global sales network enables us to respond spontaneously to the needs of our customers and to quickly meet all project-specific requirements. Together with professional external partners, BUTTING is there for you – worldwide!

Careers

BUTTING is a seventh-generation family business that has been growing steadily for 240 years. The basis for this success has always been our experienced employees.