Special pipes

Customised special pipes

Your perfect solution

Whether standardised or customised - BUTTING manufactures special pipes for clean processes if your requirements go beyond the standard.

By combining modern production technology with craftsmanship and experience, we realise special pipes - formed with precision, refined to meet your requirements:

- With surfaces as clean as the process they serve.

- With tolerances on shape and position as tight as your trust in us.

- With special geometries as unique as your application.

For processors who expect perfection - and receive it from us. Also available in nickel alloys, if required.

Nickel alloys

Special pipes made from special materials

Do you need pipes for demanding media?

Thanks to their high corrosion resistance, heat resistance and mechanical strength, pipes made of nickel alloys are used wherever you have the highest and most stringent requirements.

BUTTING manufactures pipes in highly corrosion-resistant nickel-based materials both continuously from coiled strip and individually from plate - flexibly and as required.

We have been processing nickel alloys such as Alloy 625 / 2.4856, Alloy C276 / 2.4819, Alloy 59 / 2.4605, Alloy 201 / 2.4068, Monel 400 / 2.4360 for over 40 years.

Contact us to find the optimum solution for your requirements!

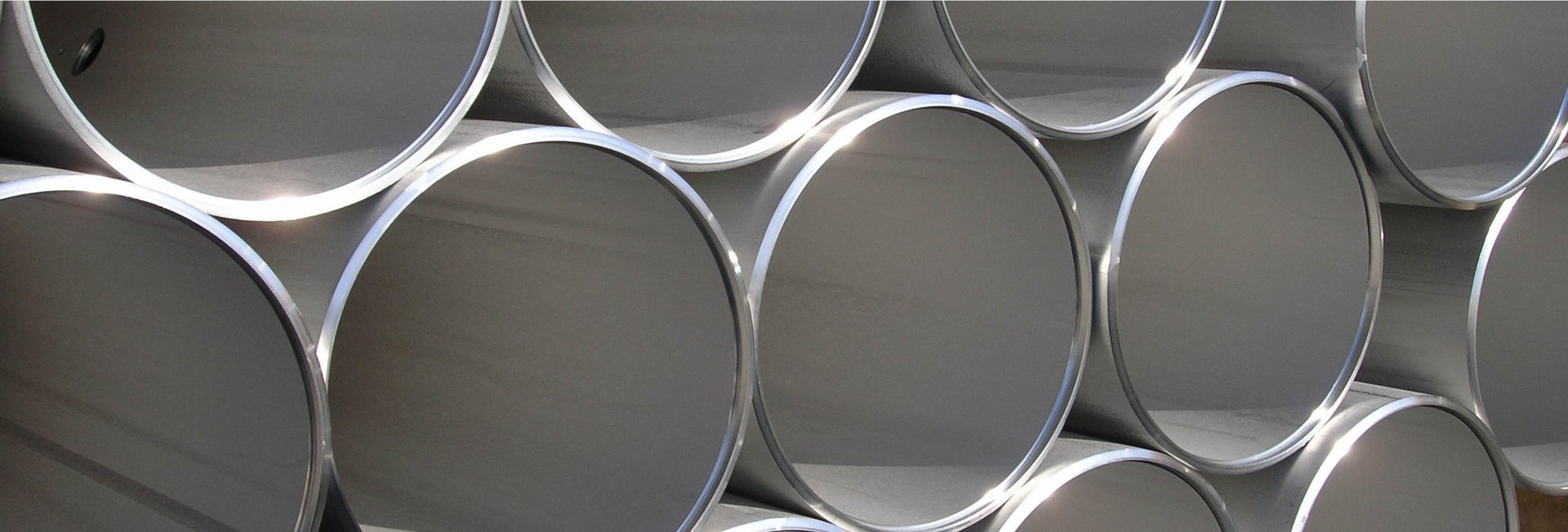

Welded stainless steel pipes

Proven across all industries

From the chemical and process industries to plant and mechanical engineering and energy technology - they fulfil the highest requirements in terms of quality and longevity. Our longitudinally welded stainless steel pipes can be found in a wide range of industries.