Our qualifications

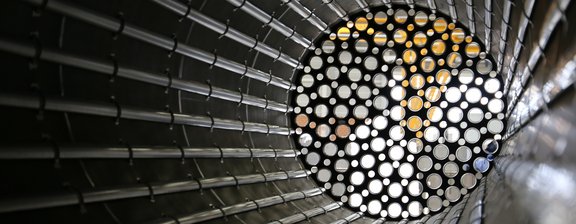

BUTTING stands for quality and reliability

Our qualifications at a glance

A broad product portfolio of stainless steels of the highest quality has been our flagship for decades. Every day, BUTTING employees are inspired by our shared excellence in the areas of materials and welding technology, production engineering and quality assurance - and thus form the basis of our quality promise.

We manufacture our products in accordance with a large number of internationally recognised standards, such as DIN EN ISO, AD 2000, ASTM, API or NORSOK. Depending on the order, BUTTING also fulfils customer-specific requirements, e.g. from BASF, Saudi Aramco, Shell or Equinor.

The result is numerous approvals for a wide variety of products, production steps and manufacturing processes within our product range:

Production site Knesebeck (Germany)

- DIN EN ISO 9001Quality Management

- DIN EN ISO 14001(Evironmental Management)

- DIN ISO 45001(Occupational Health and Safty Management)

- DIN EN ISO 50001(Energy Management)

- AD 2000-Merkblatt W0

- API-5LC

- API-5LD

- ASME / U-Stamp

- Bureau Veritas Mode II(Manufacturer approval in accordance with ship building regulations)

- DEKRA EN 9100Quality management for aerospace and defence (sub-sector certification)

- DGRL 2014/68/EU - PED

- DIN EN ISO / IEC 17025(Laboratory Accredition)

- DIN EN ISO 3834

- DIN EN ISO 1090-2

- DIN EN ISO 1090-3

- DNV GL manufacturer approval in accordance with DIN 2303

- DNV GL rules for classification - Ships (WWA)

- DVGW GW 541

- Manufacturer license for ChinaTSG D7002 – 2023 (Pipes)

- ISO 19443Quality management for nuclear energy (sub-area certification)

- Lloyds RegisterManufacturer approval in accordance with ship building regulations)

- NORSOK M-650 QTR 01 ASTM A928Type 22Cr Duplex / UNS S31803

- NORSOK M-650 QTR 02 ASTM A928Type 25Cr Duplex / UNS S32760

- NORSOK M-650 QTR 03 ASTM A358Type 6Mo / UNS S31254

- NORSOK M-650 QTR 04 ASTM A928Type 25Cr Duplex / UNS S32750

- NORSOK M-650 QTR 05 ASTM A358Type Type 565 / UNS S34565

- NORSOK M-650 QTR 06 ASTM B862Titanium Grade 2 / UNS R50400 / without heat - Treatment

- NORSOK M-650 QTR 07 ASTM B862Titanium Grade 2 / UNS R50400 / with heat - Treatment

- WHG-Approval(Specialist firm in accordance with the Federal Water Resources Act)

Production site Schwedt (Germany)

- DIN EN ISO 9001 (Quality Management)

- DIN ISO 45001 (Occupational Health and Safty Management)

- AD 2000-Merkblatt W0 / HP0

- Material labeling AD 2000

- DIN EN ISO 3834

- DIN EN ISO 1090-2

- Leak protection lining Z-65.30-632

Production site Könnern (Germany)

- DIN EN ISO 9001 Quality management

- DIN ISO 45001 Occupational health and safety management

- DIN EN ISO 50001Energy management

- DIN EN ISO 3834-2

- AD 2000 data sheet W0 / HP0

- Bureau Veritas Mode II Manufacturer approval according to shipbuilding regulations

- DGRL 2014/68/EU

- Lloyds Register Manufacturer approval according to shipbuilding regulations

- DNV rules for classification - Ships (AMMM) and Metallic Materials

- NORSOK M-650 QTR 01 ASTM A928

- NORSOK M-650 QTR 02 ASTM A928

Production site Tieling (China)

- DIN EN ISO 9001 Quality management

- DIN EN ISO 14001 Environmental management

- DIN ISO 45001 Occupational health and safety management

- ASME / U-Stamp

- EN ISO 3834-2

Customised product solutions

Solutions for many industries

At BUTTING, we manufacture according to the specific requirements of your industry, in every technically possible design and in accordance with all current regulations. We have the right solution for each of your projects.

Chemistry

Energy

Vehicle construction

Food

Aerospace

Maritime economy

Mechanical and plant engineering

Paper and pulp

Pharmaceuticals