"An International Welding Inspector is qualified, among other things, to evaluate tests on the component and draw appropriate conclusions about the welding task without having to commission an external company," explains Volker Lahmann, Head of Welding, materials & testing technology. "For example, he can travel to the construction site himself to personally clarify welding and / or testing issues with the customer on site and, if necessary, initiate follow-up investigations without the need for additional experts," Lahmann continues. Cooperating with external testing and certification bodies is just as much a part of the welding inspector's field of activity as the professional assessment of complaints and the presentation of practice-oriented solutions.

Some certification bodies and customers already require this qualification in their specifications. Since BUTTING has always been regarded as a pioneer in quality control, it is a matter of course for us to qualify our employees accordingly.

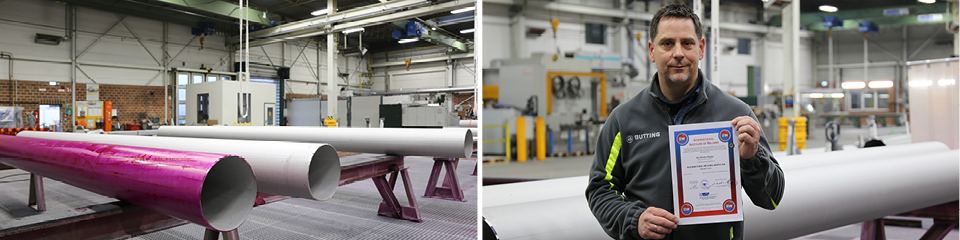

As a certified welding expert and deputy team leader for welding technology at BUTTING, Kai Dennis Engler is building on his many years of extensive previous knowledge with this further training. "I have been with the company for 28 years and in welding for 12 years. During this time, I have already attended various non-destructive tests at BUTTING.

Now being able to evaluate such tests myself and make the appropriate decisions is not only exciting for me personally, but also ensures the quality of the welded joints of our products at an early stage."

Excellent news: BUTTING could not be better positioned to meet the increasing manufacturing requirements of the customer and the certification body.

Production processes in many manufacturing companies include welding and testing. At Butting, approximately 1 500 welding procedure approval tests are currently performed in line with German and international rules. At BUTTING we use almost every modern testing procedure in the course of non-destructive testing.

BUTTING – Progress by Tradition