The Canadian end customer, based in central Alberta, is one of the leading manufacturers of plastics and chemicals for customers all over the world who produce consumer and industrial goods and packaging. A number of different piping components were required to extend the production lines.

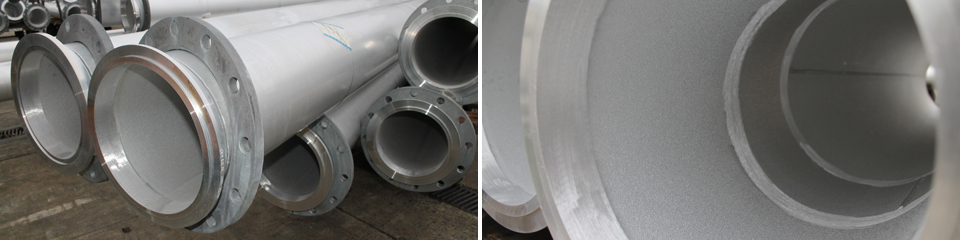

The customer selected the aluminium material for the pipes: EN AW-6060 (EN AW-AlMgSi) and EN-AW 5754 (AlMg3). More than 1 700 m of pipes, ranging in size from DN 125 / 133 x 3.0 mm to DN 600 / 609.6 x 6.0 mm were produced. Because of the characteristics of the material used, cost-effective ball blasting was sufficient to achieve the required depths of roughening. In the process, the inner surface of the product was shot blasted, using steel balls. To complete the order, more than 100 long radius elbows of up to DN 300 were produced. A number of the piping components for pneumatic conveyor systems were produced in Canada, and were complemented by late collars made from aluminium from single-part production at the BUTTING headquarter.

Careful transport of bulk materials – without abrasion or reduction in size – is crucially important for plant reliability. A special treatment of the inner surface of pipes restricts the formation of impurities, the so-called angel hair. BUTTING uses two different processes for this purpose: ball blasting and raumatic roughening. Our customers can order different depths of roughening, depending on the types of product and of transport.

BUTTING – Progress by Tradition