Our history

More than Pipes

Progress by expertise and values

In 1777, BUTTING was founded as a coppersmith's workshop in Crossen an der Oder. The coppersmith's trade demanded a lot from the workers: strength, endurance, reliability and courage were put to the test almost every day. And it is precisely these values that keep our tradition alive today and allow BUTTING to grow.

In the past 250 years, much has changed in the world, in science and research, in society and at BUTTING. Until the middle of the 20th century, our ancestors forged copper kettles for breweries. Today, we use stainless steel to manufacture components for rocket engines, among other things.

Despite all the changes, something has remained that cannot be replaced by anything else: The expertise of our employees and the traditional values that made progress at BUTTING possible in the first place and will continue to do so in the future.

Our history

1777

BUTTING is founded as a coppersmithy in Crossen an der Oder in the province of Brandenburg (in present-day Poland).

1890

Under Hermann Butting, the fourth generation to take over the business in 1877, the simple forge becomes an industrial company with series production of soldered copper pipes.

1891

The "lyre bend" becomes BUTTING's first trademark.

1912

Graduate engineer Hanns Max Hermann Butting takes over the business and becomes the fifth generation to manage the company.

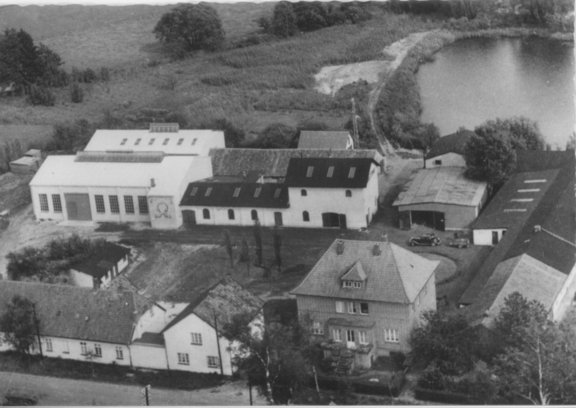

1945

As the company headquarters in Crossen is located in the eastern territories of the German Reich, it has to be abandoned due to the Second World War and its consequences. The company is rebuilt in Knesebeck, a town in the district of Gifhorn in Lower Saxony.

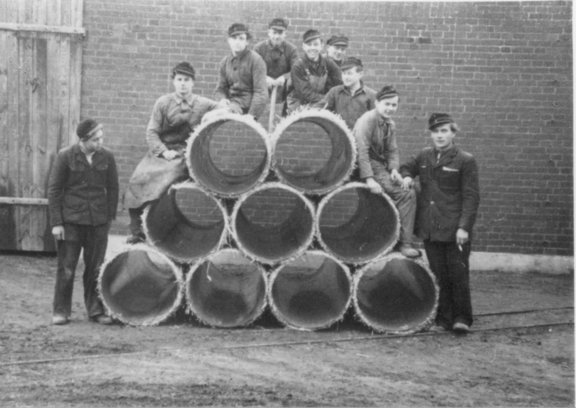

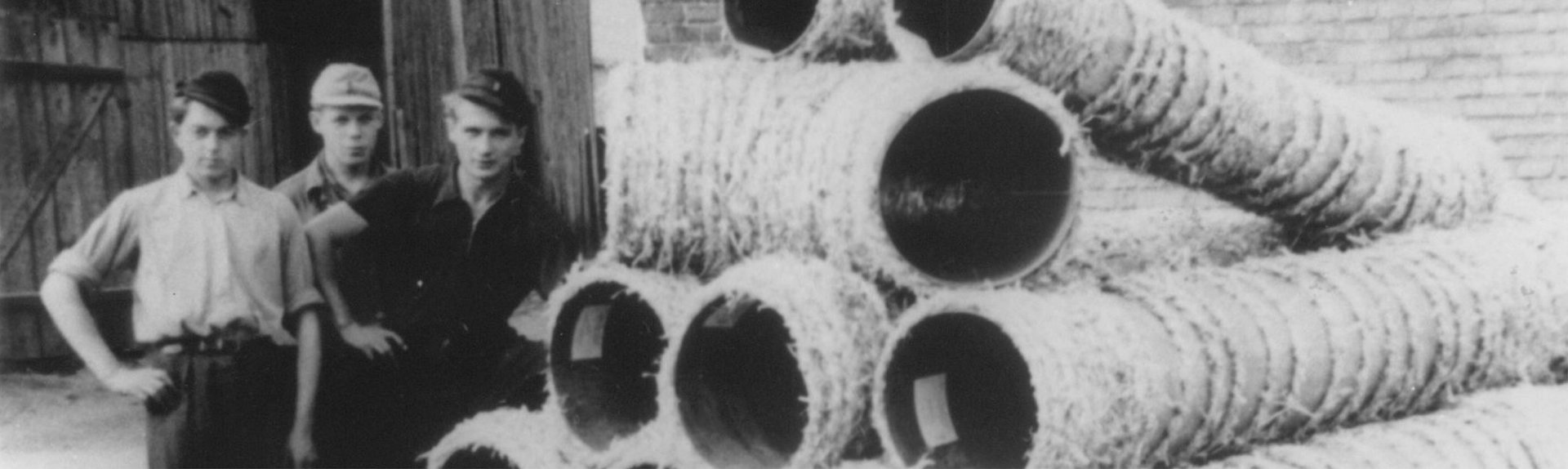

1949

Pipe production is resumed at the new site. BUTTING employs 16 people for this purpose.

1955

Dr Hannshermann Butting, the sixth generation of the family, joins the company.

1958

The traditional material copper is gradually replaced by stainless steel.

1960

BUTTING flourishes, the workforce has now grown to 120 employees.

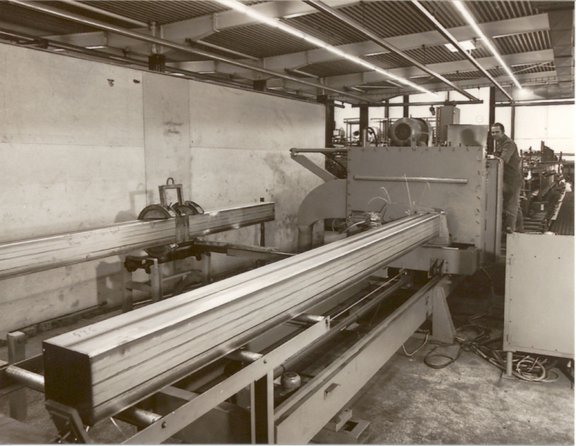

1965

Manual labour is almost completely replaced in many areas. Pressing, shearing, milling and radiography are converted to largely automated, mechanical systems for the processing of the stainless steel.

1970

Despite the advancing automation, BUTTING now employs a staff of around 300 at the Knesebeck site.

1979

The first duplex steel tubes are produced at BUTTING.

1987

Production of metallurgically clad pipes begins.

1988

BUTTING has its quality management certified for the first time by Germanischer Lloyd (now part of the German-Norwegian classification society DNV) in accordance with ISO 9002, which had been introduced just one year earlier.

1991

Shortly after the German reunification, a second BUTTING site is founded in Schwedt an der Oder. From now on, BUTTING Anlagenbau is based in the most populous town in the district of Uckermark in the north-east of the state of Brandenburg.

1994

BUTTING receives its first order to manufacture the newly developed mechanically clad BUTTING bi-metal pipes (BuBi®). These were specially designed for demanding and sensitive applications in the oil and gas industry. A corrosion-resistant BUTTING stainless steel pipe is telescopically aligned inside a carbon-manganese steel pipe and followed by mechanical bonding using a hydroforming system.

2000

Business graduate and welding engineer Hermann Butting takes over the management of the family business in the seventh generation.

2003

The number of employees at BUTTING exceeds 1,000 for the first time.

2004

BUTTING China is founded as the first foreign location, followed shortly afterwards by BUTTING Canada in Calgary, the second location outside Germany.

Hermann Butting founds the BUTTING Academy with the aim of promoting the value-oriented development of people and organisations in the region.

2007

From this year onwards, the"BUTTING Practical Days" are held regularly especially for employees from the stainless steel industry, where tried and tested expertise is imparted.

2009

A third location, BUTTING Brasil in Araquari in the state of Santa Catarina, is added to the branches around the world.

The BURG Knesebeck conference centre opens its doors for the first time as the BUTTING Academy's new training centre and from then on will make an important contribution with its inspiring atmosphere.

2011

BUTTING China establishes another production facility in Tieling. The investment optimises and expands the production facilities for vessel construction, the manufacture of piping systems and ready-to-install components.

In Brazil, BuBi® pipes for risers are laid using the reeling method for the first time in the Bacalhau offshore oil field in the pre-salt area of the Santos Basin.

2015

For the Kashagan oil field in Kazakhstan, which is owned by China National Petroleum, Eni, Exxon Mobil, Inpex, National Company KazMunayGas, Shell and TotalEnergies, BUTTING is awarded the contract to produce

170 kilometres of clad pipes. It is the largest order in the company's history to date.

2017

BUTTING takes over the stainless steel pipe manufacturer Sosta in Könnern and runs the company under the name BUTTING Könnern from December 2021. The new site produces longitudinally welded stainless steel pipes from coils and plates in lengths of 2 to 12 metres.

2018

Regular certification in accordance with international standards is an important competitive factor. These include the European standard FprEN 9100:2016, which verifies compliance with quality requirements for companies in the aerospace and defence industry. Following initial certification in accordance with EN 9100 in summer 2017, the company successfully transitioned to the current standard in May 2018. BUTTING has been certified to EN 9100 ASD EASE (Second Party) for decades.

2019

Two new companies are founded in China: BUTTING International Engineering is based in the Hong Kong Special Economic Zone and BUTTING Engineering Management in the capital Beijing.

In Germany, the GluBi® pipe developed by BUTTING receives the "Statement of Feasibility" from DNV, which includes a complete risk assessment and risk minimizationn measures. An elementary step towards series production. The GluBi® pipe is a glued mechanically bonded pipe that can be laid using the reel-lay method without the use of internal pressure or having to increase the wall thickness of the corrosion-resistant liner.

2020

In mid-2020, BUTTING Anlagenbau in Schwedt takes over the family business TEXTORIS Apparate-und Rohrleitungsbau in Düren and will be able to draw on the many years of experience and expertise of the employees of a recognised company in the future.

BUTTING can report a further takeover in southern Germany: Schwanner GmbH in Burgkirchen, Bavaria. This company was also founded as a traditional forge, but has developed into a global leader in vacuum technology. It is be integrated into the Group under the new name BUTTING CryoTech.

2021

A second BuBi® production line is built and commissioned at the headquarters in Knesebeck.

In September 2022, the first project for vacuum-insulated transfer lines (VIP) is successfully completed for an air separation unit (ASU) in Saudi Arabia. The strengths of both pipe production and plant engineering at BUTTING complement each other perfectly with BUTTING CryoTech's special expertise in vacuum-insulated pipes.

In December, BUTTING's environmental management at the production site in Tieling, China is also certified according to ISO 14001. The certification once again confirms BUTTING's commitment to environmental management and environmentally conscious and sustainable behaviour.

2022

The new sites have once again significantly increased the size of the workforce. In January 2022, around 1,980 employees work for the BUTTING Group.

As part of the ongoing success and expansion, a sales office is opened in Dubai. The United Arab Emirates have been the hub of BUTTING's business activities in the Middle East and North Africa (MENA) region for several years.

2023

Vacuum-insulated pipework (VIP) is manufactured for the first time in Knesebeck's one-off production facility - and successfully delivered. In this unique pilot project, BUTTING CryoTech is responsible for detailed engineering and creates all drawings in its own CAD office. Despite a tight schedule, the entire order was successfully delivered at the beginning of May 2023.

2024

BUTTING in Knesebeck is awarded a coveted gold medal by EcoVadis in its sustainability rating in May. This recognition reflects the company's comprehensive commitment to sustainability and social responsibility. The prestigious gold medal places the headquarters in Knesebeck in the top 5% of all companies assessed worldwide.

2025

In January 2025, the renowned assembly company PrePipe Oy from Finland joins the BUTTING Group with around 50 employees.

At the beginning of the year, the BUTTING Group also expands its range of plant engineering services by opening an engineering office in Oberursel - BUTTING Plant Engineering.

In June 2025, BUTTING in Knesebeck was awarded the platinum medal by the internationally renowned sustainability platform EcoVadis - the highest rating awarded.

The owner

Hermann Butting

Hermann Butting is the seventh generation of his family to lead the BUTTING Group as Managing Partner since 2000. In addition to solid professional expertise, he considers practiced values to be crucial for the sustainable success of his management role. This is why the business graduate completed additional training as a welding engineer.

BUTTING Group

Our management

As an international company, we at BUTTING know that management must react dynamically in a changing world. But despite all the flexibility, there is one constant: all our managers share an open, appreciative attitude towards employees, colleagues and customers and base their behaviour on the management principles of our company.