Mechanical treatment

Mechanical processing

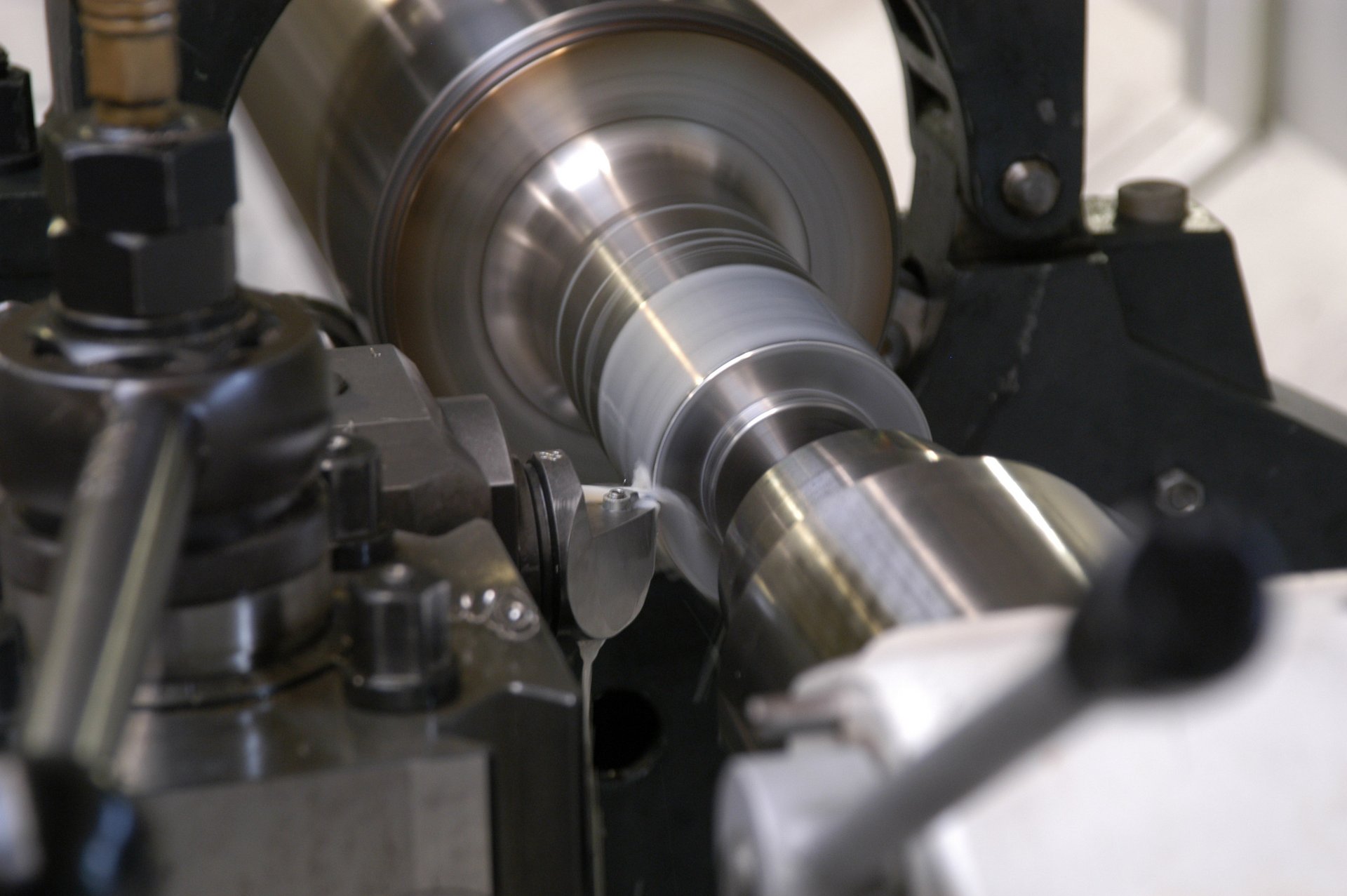

Turning, milling, drilling

Precise results during further processing are the quality criterion for our speciality tubes and ready-to-install components. We help fulfil your economic and technological requirements with the machining used with our stainless steel pipes. This enables us to guarantee the optimum quality of the customised product solutions developed for you.

We offer you a wide range of machining and thermal processing options:

- Turning

- Milling

- Drilling

- Broaching

We manufacture complete parts and components in just one clamping operation on our in-house turning and milling machines.

Our own production centre

Our production centre is equipped with modern CNC turning and milling technology. Whether for individual items or series production, we develop optimised solutions for your tasks every day. In addition to corrosion-resistant steels and heat-resistant alloys, special alloys are also processed depending on the area of application.

The versatility of the machining centre is characterised by a maximum machining diameter of 700 mm and two overhead tool turrets with driven tools. Complete machining in the form of turning and milling in a single set-up increases the efficiency of the machining processes. A quick-change system for clamping devices also ensures a high degree of flexibility.

Customised product solutions

Solutions for many industries

At BUTTING, we manufacture according to the specific requirements of your industry, in every technically possible design and in accordance with all current regulations. We have the right solution for each of your projects.

Chemistry

Energy

Vehicle construction

Food

Aerospace

Maritime economy

Mechanical and plant engineering

Paper and pulp

Pharmaceuticals