Vacuum-insulated pipelines

Cryogenic transfer systems

Ideal solution for cryogenic media

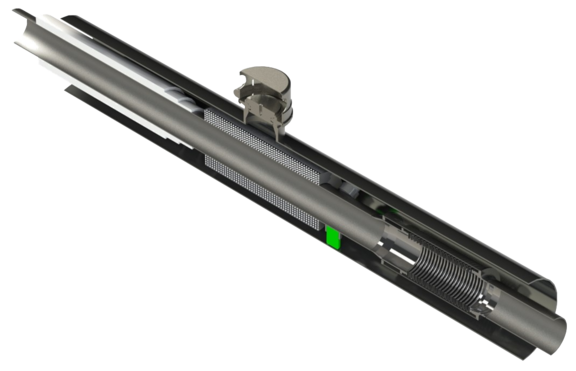

Vacuum-insulated transfer lines from BUTTING CryoTech are the ideal solution for the transfer of all common cryogenic media (LH2, LHe, LN2, LOX, LAR). Our pipes are available with inside diameters from DN10 to DN500 and combine vacuum and multi-layer insulation to minimise heat input and maximise efficiency.

Particularly safe - particularly efficient

Since 1984, BUTTING CryoTech has manufactured more than 50,000 metres of vacuum-insulated transfer lines. The use of corrosion-resistant materials, integrated compensators, absorption material and spacers with the lowest thermal conductivity ensure safety and a long service life. This is why customers around the world trust our expertise.

Top expertise from BUTTING CryoTech

Vacuum technology

Our engineers develop solutions for a long service life and minimised heat loss. Thanks to our production capacities, we are able to manufacture large nominal diameters and quantities of transfer lines in consistently high quality.

Discover the many advantages for you:

- Optimum use of materials for the best vacuum values

- Decades of experience in manufacturing

- Reduced number of expansion joints thanks to our own design

- Long service life thanks to corrosion-resistant materials

- Minimised heat input thanks to effective insulation

On the way to a green future

Transfer systems for LNG

Until the transformation of our energy system to renewable energies such as green electricity, hydrogen and biogas is complete, liquefied natural gas (LNG) will play an important role in heat generation and as a raw material in industry. The BUTTING CyroTech engineering team will work closely with you to develop a customised solution for your specific LNG project.

Best protection against external influences

Transporting liquefied natural gas (LNG) at a temperature of -160 °C requires the best possible insulation of the transfer system in order to minimise the heat input and thus the evaporation rate. The vacuum insulation technology from BUTTING CyroTech curently offers unrivalled protection against external influences on the system.

Systems for efficient transfer

The cost-efficient transfer of liquefied natural gas (LNG) requires piping systems of much larger dimensions than is the case for other cryogenic liquids. Our proprietary technology enables flow rates of 6,000m3/h with nominal diameters of up to DN1000. We also ensure a heat input of <2.5 W/m2 for these sizes.

Energy source of the future

Transfer systems for hydrogen

Hydrogen has the potential to become an important energy source of the future. Liquid hydrogen (at -252.9 °C) places particularly high demands on transfer systems. To avoid losses and to ensure optimum safety, the transfer lines must be particularly well insulated. This is where BUTTING CyroTech's vacuum technology proves its worth.

Minimal temperature losses

In order to separate the extremely different temperatures between the external environment and the medium flowing in the process pipe in the best possible way, many factors of our vacuum-insulated pipelines are optimised. The materials of the vacuum jacket and the process pipe, distances, wall thicknesses and the distances used play a decisive role, as do the insulation material and the duration for which the vacuum is applied.

Less space - more safety

Thanks to their double-walled construction, our vacuum-insulated transfer lines offer excellent insulation performance and diffusion density - comparable to multi-layer systems made of materials such as PIR/PUR, Foamglas, Armaflex, Perlite or Misselon, but without the disadvantage of a larger pipe diameter.

From engineering to maintenance

The complete package

Your project is what drives us. Our experts work with you to develop the ideal solution to ensure cost efficiency and the lowest possible heat input over the entire service life of the transfer lines. The vacuum-insulated piplines are planned in the factory, built in prefabricated lengths and shipped globally. You will receive the necessary documentation in line with the local requirements of the area of application.

We offer professional on-site installation supervision by our highly qualified personnel. If required, we can also take care of the maintenance of your vacuum-insulated lines (e.g. post-evacuation).