Paper and pulp

Pulp and paper industry

Your innovative partner

Thanks to our extensive expertise in the processing of stainless steels, we support the paper and pulp industry with pioneering solutions for a wide range of requirements. We offer you pipelines and vessels in conjunction with additional services such as engineering, assembly or supervision. Worldwide, from a single source.

Service from A-Z

An important cornerstone is our all-round service: from CAD planning, vessel and pipeline construction and cost-saving prefabrication to assembly and the supervision of other companies on your construction site, we take responsibility for the optimum implementation of your project and thus increase profitability.

Rick Herbelschmidt

Sales Manager

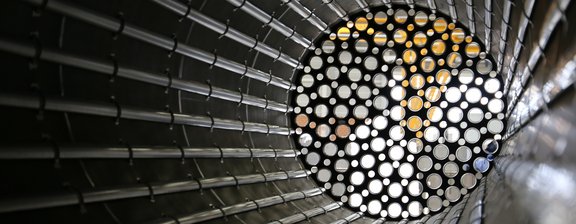

Prefabricated pipes

rick.herbelschmidt@butting-schwedt.de

Send mail

Rick Herbelschmidt

Sales Manager

Prefabricated pipes

rick.herbelschmidt@butting-schwedt.de

Send mail