Materials engineering

Unrivalled expertise

Our knowledge creates safety

Our unique expertise in materials technology has always been one of BUTTING's core competences. Our fabricationprogramme offers you a wide range of high-performance materials for industry-specific applications. We are on hand to advise you on the choice of material and answer any questions you may have about corrosion, heat or surface treatment.

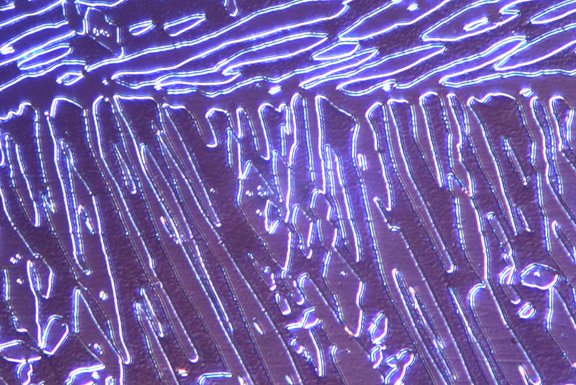

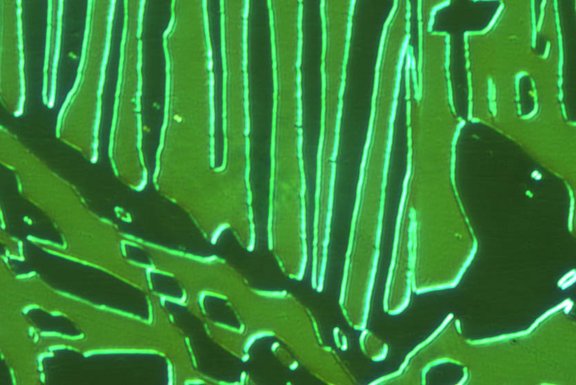

Avoid corrosion

The aim of processing stainless alloys is to prevent corrosion. BUTTING processes a variety of steels, alloys and clad materials of different grades to counteract almost every possible form of corrosion in a wide range of industries. The right choice depends on the conditions of the subsequent application.

Customised for every application

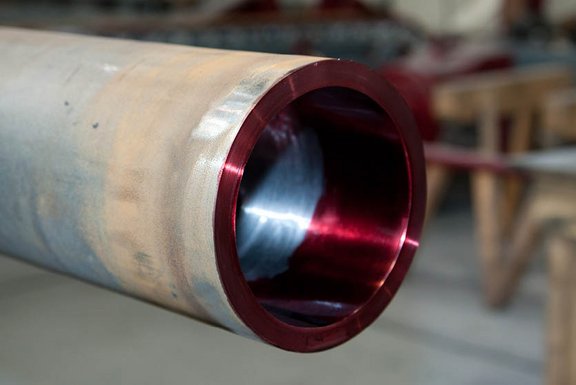

Wide range of high-performance materials

We offer you optimal, customised solutions for piping systems, tanks and special components as part of your special project. With our proven expertise in materials technology, we are your reliable specialist for processing austenitic steels, special alloys and titanium as well as duplex, superduplex and lean duplex.

- Austenitic steels

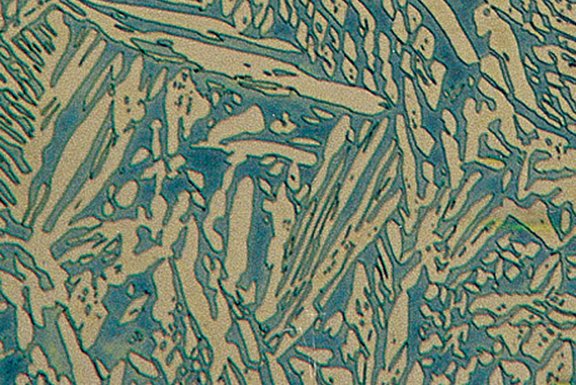

Austenitic steels are primarily used in the chemical and pharmaceutical industries, in the paper and pulp industry and for household appliances. They are also used in food and beverage production and processing, in apparatus and container construction. - Austenitic-ferritic steels

Austenitic-ferritic steels, known as duplex steels, are ideal for almost all offshore installations, such as vessels and process pipes on drilling platforms or for use in seawater desalination plants. - Nickel alloys

The nickel alloy group has excellent localised and acid corrosion resistance. This benefits many applications, particularly in the chemical and pharmaceutical industries as well as in oil and gas production.

Customised to your needs

Our variety of materials

Material group

|

Exemplary materials

|

|---|---|

Stainless steels (austenitic)

|

1.4306, 1.4307, 1.4541, 1.4404, 1.4571, 1.4435, 1.4438, 1.4539, 1.4529, 1.4547, 1.4565

|

Stainless steels (austenitic-ferritic, duplex, super duplex, lean duplex)

|

1.4462, 1.4410, 1.4501, 1.4507, 1.4162, LDX2101®, AL2003TM, 1.4362

|

Clad steels

|

Carbon or carbon-manganese steels according to ISO, DNV or API clad with e.g. 1.4404, 1.4539, 2.4858, 2.4856

|

Highly corrosion-resistant alloys

|

2.4858, 2.4856, 2.4610, 2.4605, 2.4633, 2.4819, CW354H

|

Heat-resistant steels (austenitic)

|

1.4835, 1.4878, 1.4828, 1.4841, 1.4845, 1.4876

|

Stainless steels (ferritic)

|

1.4003, 1.4510, 1.4509, 1.4512, 1.4521

|

Non-magnetisable steels

|

1.3952, 1.3964, 1.3974

|

Titanium and titanium alloys

|

3.7025, 3.7035, 3.7034

|

Our experts

Expertise in demand worldwide

Before selecting materials for a project, you should consult with the BUTTING experts, who are always on hand to advise you with all their experience in the areas of material selection, corrosion and heat treatment. For this reason, our expertise and our products are used worldwide in projects with the highest technical requirements.

We find the perfect solution

Taking into account the availability of primary materials, we analyse your specific requirements and make project-specific recommendations for the use of appropriate materials. Our metallurgists, welding engineers and production staff are happy to take on your individual challenges and develop innovative concepts and customised solutions for you.

Reacting to circumstances

Corrosive media

- Chloride-containing attack agents

For stresses in connection with halogen ions (chlorides, fluorides, iodides, bromides), we recommend the use of steels with increasing chromium and molybdenum contents. Copper-nickel alloys, high-molybdenum nickel alloys and titanium are suitable. - Sulphuric acid attack agents

Molybdenum and copper additives can help to reduce the concentration of sulphuric acid. Chromium and silicon have proven themselves as corrosion protection against oxidising sulphuric acids. Lead linings and nickel alloys are suitable for special stresses. - Phosphoric acid attack agents

Austenitic molybdenum-alloyed steels have proven their worth, particularly in the aggressive environment of pure phosphoric acids, even in high temperature ranges. In contrast, highly alloyed special steels should be used in contaminated phosphoric acids. - Organic corrosive agents

Stainless steels are resistant to a large number of organic solvents and chemicals such as greases, oils, benzene, phenols and other carbon-hydrogen compounds In addition, unlike unalloyed steels, they are not contaminated by traces of rust.

Customised product solutions

Solutions for many industries

At BUTTING, we manufacture according to the specific requirements of your industry, in every technically possible design and in accordance with all current regulations. We have the right solution for each of your projects.

Chemistry

Energy

Vehicle construction

Food

Aerospace

Maritime economy

Mechanical and plant engineering

Paper and pulp

Pharmaceuticals