Cutting

Cutting and separating

Plasma, Laser and water jet

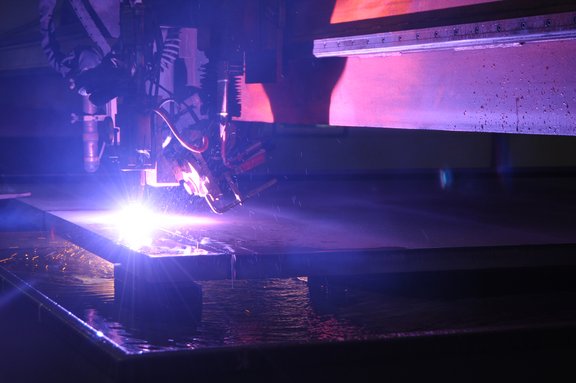

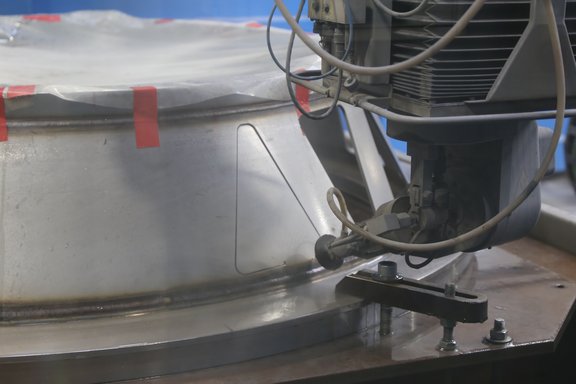

BUTTING uses state-of-the-art cutting processes for the dimensionally accurate processing of stainless steel. Depending on the requirements, Plasma, Laser or water jet cutting are used - from fast and economical cuts to high-precision contours for complex geometries.

Depending on the material, geometry and application, each cutting process offers specific advantages. The choice of suitable cutting process is made on an individual basis - together with our customers, we determine the optimum solution for their specific requirements.

Fast and accurate

Versatile laser technology

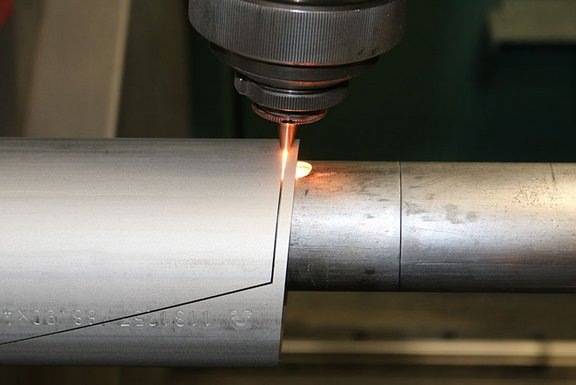

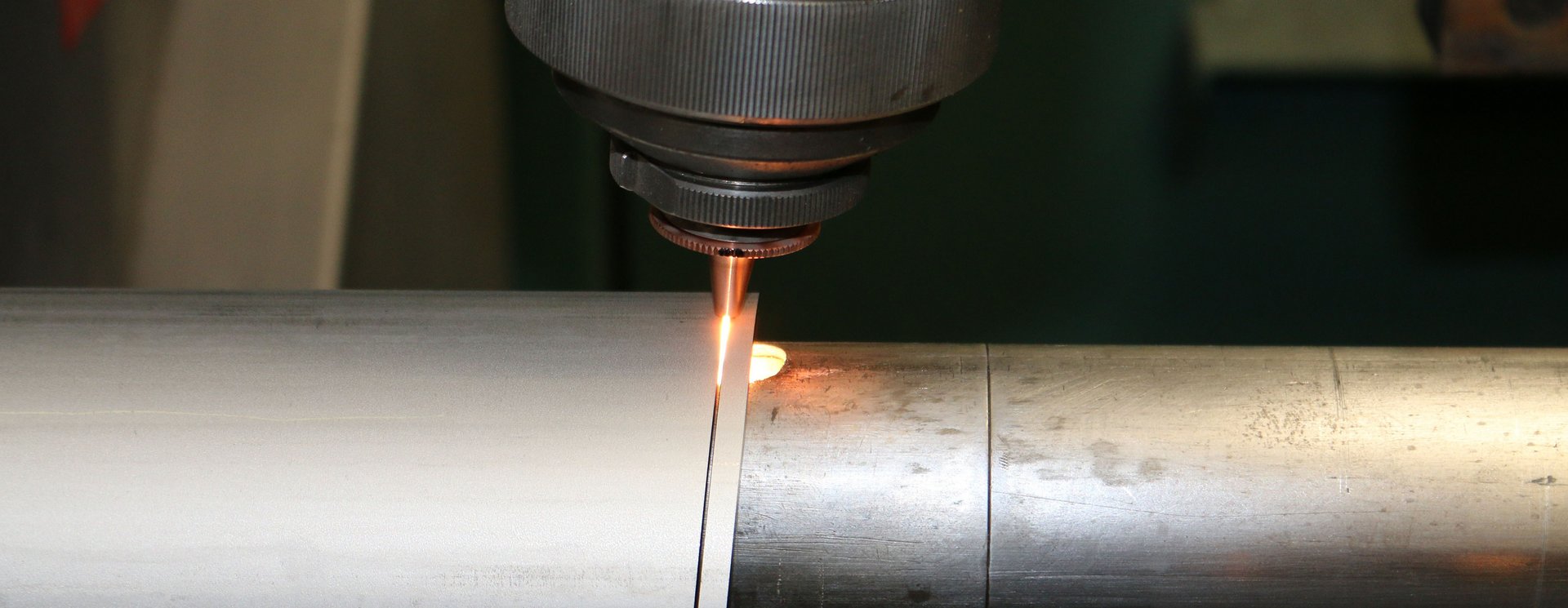

At BUTTING, innovative laser technology offers you numerous options for further processing - with a high level of cost-effectiveness. In addition to its high cutting speed, laser cutting impresses with the realisation of complex cutting geometries and notches with a wall thickness of up to 10 mm - without deformation or burrs and in compliance with the tightest tolerances.

The use of laser technology impresses with

- High cutting speed

- Three-dimensional contour variety

- Reproducibility

- Uniform, burr-free cuts

- Compliance with exact tolerance specifications, including squareness

- Very small heat-affected zone at the cutting edge

BUTTING offers you fully automatic laser cutting systems with a 3D focussing head that can also process tubes or profiles in a vertical and up to 45° inclined cutting position. This effective and efficient process for cutting through various materials and substances ensures accurate reproducibility in series production.

Customised product solutions

Solutions for many industries

At BUTTING, we manufacture according to the specific requirements of your industry, in every technically possible design and in accordance with all current regulations. We have the right solution for each of your projects.

Chemistry

Energy

Vehicle construction

Food

Aerospace

Maritime economy

Mechanical and plant engineering

Paper and pulp

Pharmaceuticals