Bending

Pipe bending

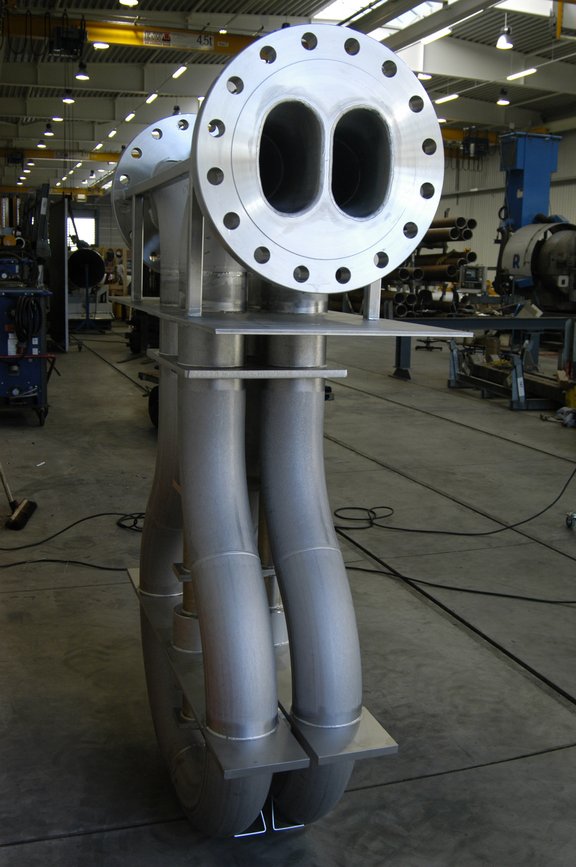

Precise geometries with a system

BUTTING offers sophisticated solutions for bending pipes with the highest precision - from classic bends to complex free-form bends in several planes. With our all-electric bending cell and state-of-the-art processes, we realise individual customer requirements economically and reproducibly.

Processes & possibilities

- Mandrel bending: Ø 3 to 168 mm

- Free-form bending: Ø 25.4 to 130 mm, multi-layered and multi-spaced according to isometrics with customised radius

- Roller & roll bending: for large radii and slim pipe bends

- Two-shell construction: for complex geometries and special applications

- Large bend production: from 3 × D up to Ø 323.9 mm

Special features

- Bends according to drawing, isometry or individual specification

- 3D multiple bends in various degrees and planes

- Production with high-quality stainless steels

- Wall thicknesses up to 8.0 mm

Quality saves costs!

The use of our bends and free-form bends helps to realise potential savings. Subsequent heat treatment is not necessary for cold-formed bends from BUTTING. The use of single and multiple bends saves on various fittings. This minimises the amount of welding work and testing required - and reduces your project costs.

Customised product solutions

Solutions for many industries

At BUTTING, we manufacture according to the specific requirements of your industry, in every technically possible design and in accordance with all current regulations. We have the right solution for each of your projects.

Chemistry

Energy

Vehicle construction

Food

Aerospace

Maritime economy

Mechanical and plant engineering

Paper and pulp

Pharmaceuticals