Areas of application

Oil and gas

Since 1978, BUTTING has been manufacturing flowlines, risers and pipes for topsides (FPSO platforms), as well as line pipes of the highest quality for the oil and gas industry.

Proven for decades

Partner to the oil and gas industry

Since 1978, BUTTING has demonstrated its expertise in the oil and gas industry with a wide range of product solutions made of clad and corrosion-resistant materials for onshore and offshore projects.

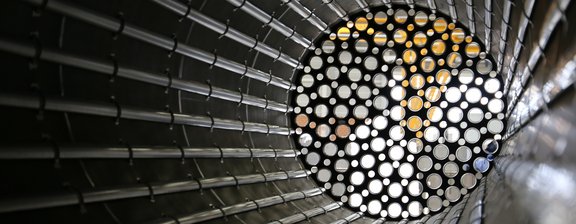

In addition to mechanically and metallurgically clad pipes, our wide range of products also includes ready-to-install clad spools and longitudinally welded stainless steel pipes. For example, we manufacture flowlines, risers and pipes for topsides (FPSO platform) as well as line pipes for the use in deepwater and high-temperature applications.