Thomas Schüller, Managing Director of BUTTING, is convinced of the value of the innovation: "We know that the laying process is an increasingly important factor in the selection of clad pipes. At the moment, reeling is the most cost-effective process for laying piping components and risers. In the light of this, we have developed a new product that reduces laying costs as well as offering potentially lower material costs."

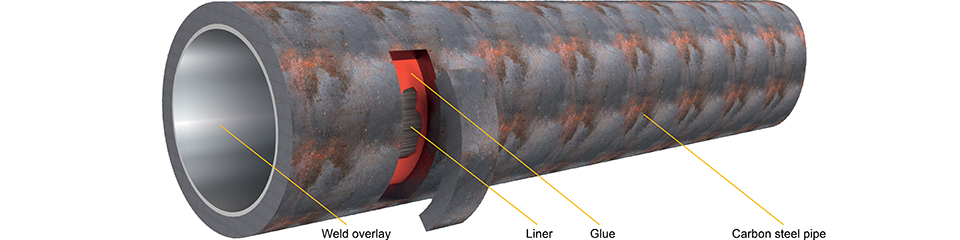

The principle behind the pipe is very innovative: The basis is a mechanically lined BuBi® pipe, which features an additional special adhesive between the carbon-manganese steel and the corrosion-resistant liner. The production process for the GluBi® pipe corresponds to 90 % of the production process for the BuBi® pipe. Thus a time-honoured and tested process can be employed, whose reproducible quality level is universally recognised.

Following extensive testing, Thomas Schüller is already convinced: "The results show that the BUTTING GluBi® pipe is a reel-capable, mechanically lined pipe. Over the coming months, we will reach other milestones in the fields of development and DNV GL qualification."

Benefits at a glance:

BUTTING – Progress by Tradition

|