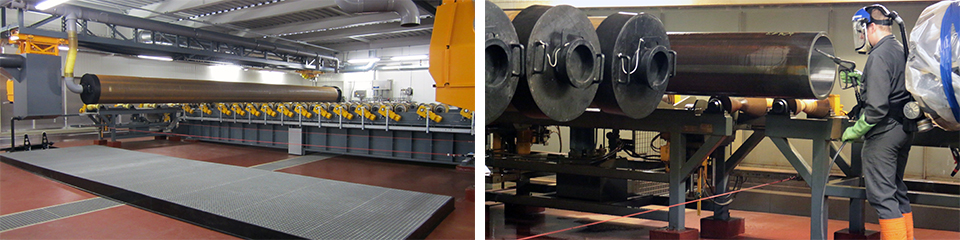

BUTTING has been manufacturing clad pipes for nearly 30 years. The new inner pipe pickling equipment has completed the steel plate pipe production cycle of the metallurgically clad pipes and limited the space for the production of the pipes to two workshop complexes. As a result, some 1 700 metres per pipe of transportation within the plant before and after pickling could be saved. Thus optimisation of the entire production process has been achieved, enabling customers to gain a cheaper product and faster production.

The new inner pipe pickling equipment pickles metallurgically clad pipes with a minimum inner diameter of 135 mm up to a maximum outer diameter of 762 mm. By agreement, even larger pipe diameters are possible.

With regard to pickling processes, BUTTING has again demonstrated its innovatory power. In addition to the familiar spray pickling process, already performed successfully in the Kashagan project, the newly developed liquid pickling process can also be used in the plant. Thanks to the employees’ expertise and longstanding experience in the surface finishing of clad pipes, BUTTING has been able to develop this new process. Liquid pickling promises not only shorter pickling times, but also better pickling results. It is currently still in the optimisation phase.

“The new equipment and the innovative pickling process will allow BUTTING in future to improve the quality of the pickled pipes and take advantage of a greater volume capacity,” explains Henning Lütkemüller, head of pipe manufacturing from plates at BUTTING.

The equipment is subject to the German Federal Immission Control Act (Bundesimmissionsschutzgesetz, BImSchG), and is therefore subject to authorisation. Since BUTTING is in a water protection area, special conditions must also be complied with. Lütkemüller explains: “BUTTING is committed to conserving resources, protecting the environment and acting in harmony with mankind and with nature. Adherence to the ecological conditions is therefore especially close to our heart.”

BUTTING – Progress by Tradition